Theoretically all aluminium sheets metals can be made into the five thickness ranges above but some are usually made into thin sheets and others thicker sheets.

6061 aluminum sheet thickness tolerance.

0 125 to 0 374 0 0015 aluminum.

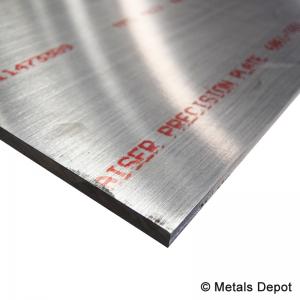

6061 aluminum sheet precision ground t651 temper precision tolerance astm b209 0 25 thickness 12 width 18 length 4 9 out of 5 stars 12 96 71 96.

Aluminum is a general purpose alloy commonly used in extrusions and is also available in sheet metal.

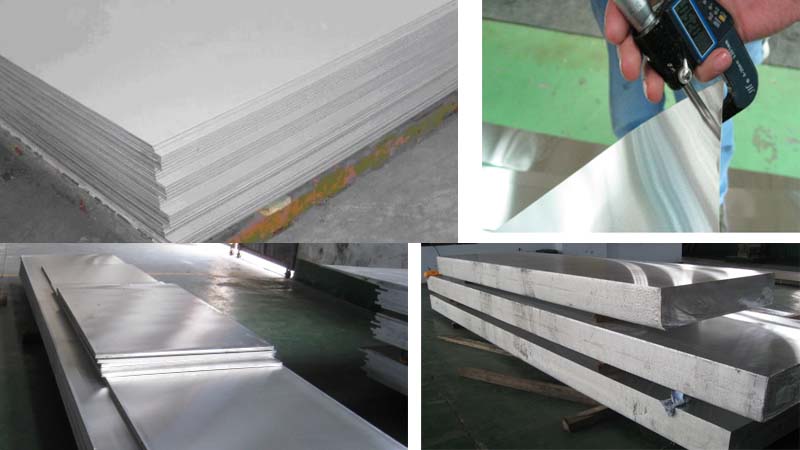

6061 t651 aluminum plate has a tensile strength range of 42 45 ksi and conforms to ams qq a 250 11 asme sb209 and astm b209.

The 6061 aluminum alloy is a general purpose material that combines good corrosion resistance strength machinability and weldability.

However it is not recommended for sheet metal work because it tends to crack on the outside radii once it passes its yield and therefore requires a much larger radii to be able to bend properly.

To reflect manufacturing difficulty the tolerances for alloys 5251 5083 6082 are now wider than this although still a little tighter than in bs1470.

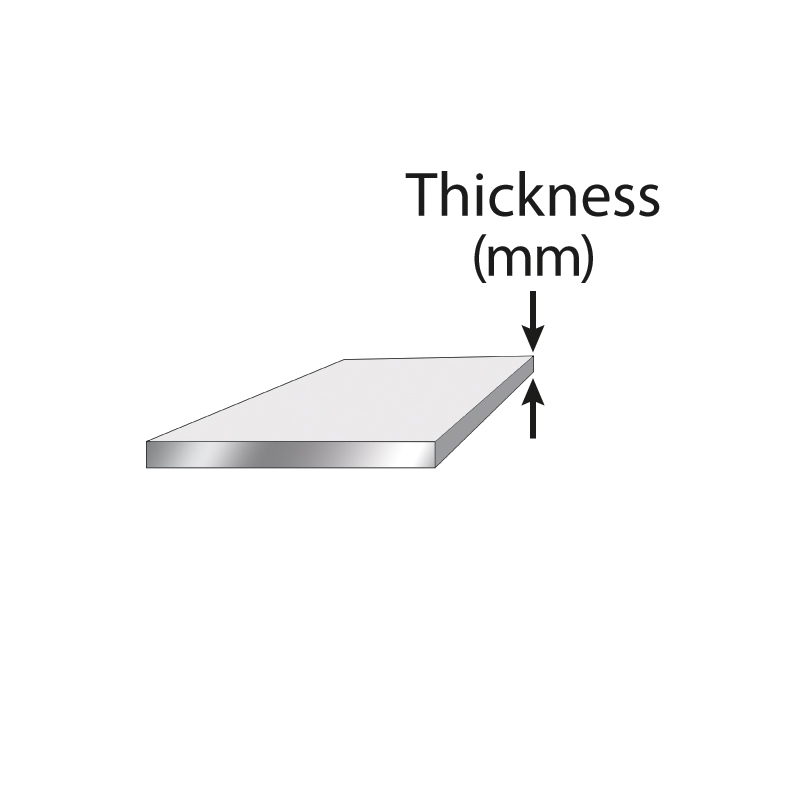

About aluminum sheet thickness tolerances.

6061 aluminum sheet plate offers a combination of higher strength good corrosion resistance and machinability making the 6061 grade the most widely used aluminum sheet and plate grade available for all types of fabrication projects the general purpose 6061 aluminum sheet plate is heat treatable resists cracking due to stress and is easy to weld and machine but limited on formability.

2011 t3 2024 t4 6061 t6 t651 cold finish.

6061 aluminum is also very easy to machine.

For example 1000 series like 1050 1060 and 1070 are usually thin or regular sheets while 6061 and 7075 aluminium are usually thicker sheets.

Aluminum sheet thickness tolerances 1100 3003 5052 6061 2024 7075 1100 3003 5052 6061 2024 7075.

Call for specific tolerance if needed.

The 6061 aluminum sheet with t651 temper meets american society for testing and materials international astm b209 standards and has been ground to a precision tolerance.

Length and width tolerances these tend to be tighter and are now all on the plus side i e.

We work with nominal thicknesses so it s important to know the thickness tolerance on the material you chose in order to know if the final product will be suitable for your application.